Notes

La madera en el arte taino de Cuba

Created by Miguel Sague Jr Aug 22, 2024 at 2:46am. Last updated by Miguel Sague Jr May 5, 2025.

AKWESASNE NOTES history

Created by Miguel Sague Jr Jun 12, 2023 at 4:15pm. Last updated by Miguel Sague Jr Jun 12, 2023.

registration form art all night Pittsburgh

Created by Miguel Sague Jr Apr 17, 2023 at 10:58am. Last updated by Miguel Sague Jr Apr 17, 2023.

Events

-

Labelling Machine

- Female

- Gadsden, AL

- United States

- Share on Facebook MySpace Tweet

- Blog Posts

- Discussions

- Events

- Groups

- Photos

- Photo Albums

- Videos

RSS

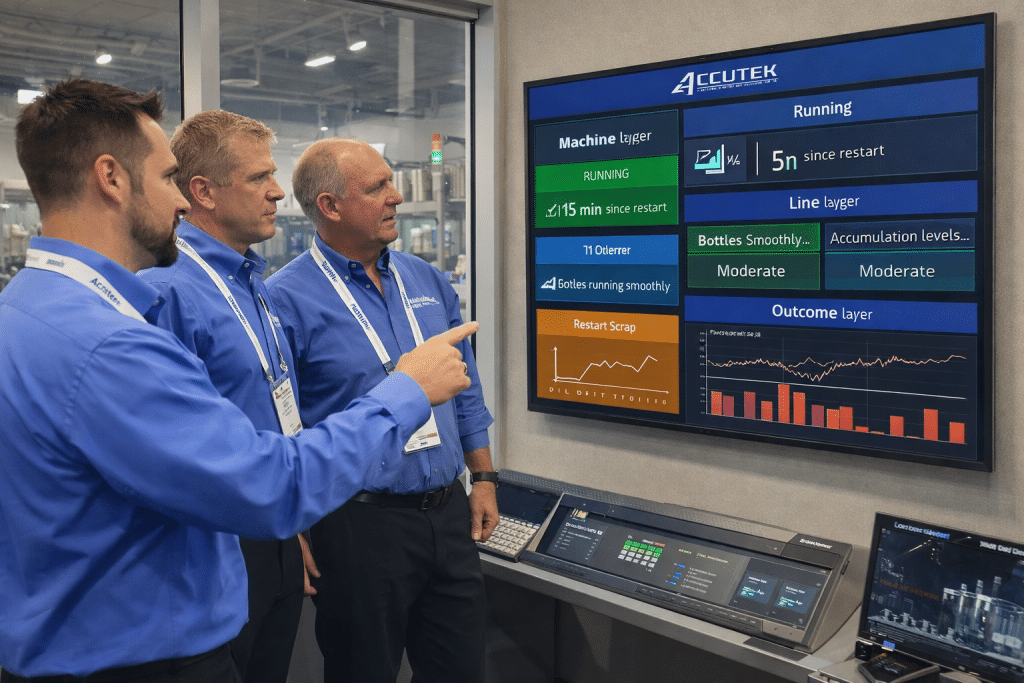

Packaging Line Data Visibility in the USA: How Real-Time Metrics Prevent Downtime and Waste

Modern packaging lines make data all day. Many plants still run blind.

Alarms flash. Screens change. Operators react. Managers see reports later.

By then, time and material are lost.

In U.S. factories, the real gap is not tech. The gap is clear, real-time visibility of packaging machines working together.

This article explains why visibility matters, what plants miss, and how better metrics cut waste and downtime on packaging machinery without slowing output.

Why visibility matters

Weak visibility causes three problems.

- Teams fix issues after losses.

- Small failures stay hidden.

- People get blamed, not systems.

In the United States, this costs money because labor is high and schedules are tight.

Good visibility turns guesswork into control.

What most plants miss

Most plants collect data but watch the wrong signals.

- Short micro-stops on packaging machines vanish in average downtime.

- The first minutes after a stop are the riskiest.

- Bottle spacing and buffers are rarely visible.

- Fill drift can rise slowly.

- One packaging machine can look fine while the line struggles.

The biggest losses are small and frequent.

| What plants miss | What happens | Business impact |

|---|---|---|

| Micro-stops | Many short pauses | 20–45 minutes lost per shift |

| Restart scrap | Defects spike after stops | 80–200 bottles wasted |

| Fill drift | Volume moves out of spec | Rework and recall risk |

| Flow instability | Bottles bunch or tip | More label errors |

| Machine misalignment | One station runs too fast | Frequent nuisance stops |

Why dashboards fall short

Old dashboards show averages.

They show speed, total downtime, and total scrap.

They rarely show:

- scrap spikes after restarts,

- which machine caused micro-stops,

- when flow went bad.

What strong visibility looks like

Strong visibility works in three layers.

Machine layer

At each packaging machine, operators see status, last fault, and time since restart.

Line layer

Teams see buffers, flow, and speed match.

Business layer

Leaders track scrap per hour, restart scrap, micro-stops, and fill trends.

When these layers align, waste falls.

How Accutek improves visibility

Accutek builds visibility into line design, not a bolt-on screen.

We make packaging machines easier to read and faster to fix.

Clear controls

Real-time status and simple fault messages reduce guessing.

Connected lines

We link machines across packaging machinery.

Teams can see speed match and bottlenecks before scrap appears.

Smarter restarts

Restart logic is coordinated across the line.

If scrap rises after a stop, teams adjust sequencing, not speed.

Trend tracking

Plants can watch fill drift, micro-stops, restart scrap, …

The post appeared first on Accutek Packaging Eqpt.: Filling, Capping, Labeling Machines.

Gifts Received

Labelling Machine has not received any gifts yet

Labelling Machine's Page

Profile Information

- About Me:

- I'm catherine martin, 29 years old and i currently working as Content Writting at ATHENA

- Occupation:

- writer

- Education:

- college grad

- Contact Information:

- 714-471-3666

- Research Interests:

- indigenous people

© 2026 Created by Network Financial Administration.

Powered by

![]()

Comment Wall

You need to be a member of Indigenous Caribbean Network to add comments!

Join Indigenous Caribbean Network